Metal Injection Molding (MIM)

Metal Injection Molding (MIM)

If you want to manufacture small parts with high strength and precision requirements, Unison Tek can help you manufacture them through the MIM process.

What is Metal Injection Molding?

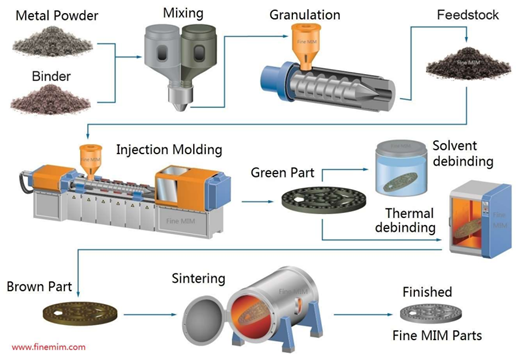

Metal Injection Molding (MIM) is an advanced manufacturing technology that combines plastic injection molding technology with powder metallurgy technology. It is an efficient and cost-effective manufacturing method, especially suitable for manufacturing small, complex, high-performance metal parts.

In addition, for other machining process: CNC Turning Parts, CNC Milling Parts, Stamping Parts. Please also visit our machined parts we made Machined Parts.

Process

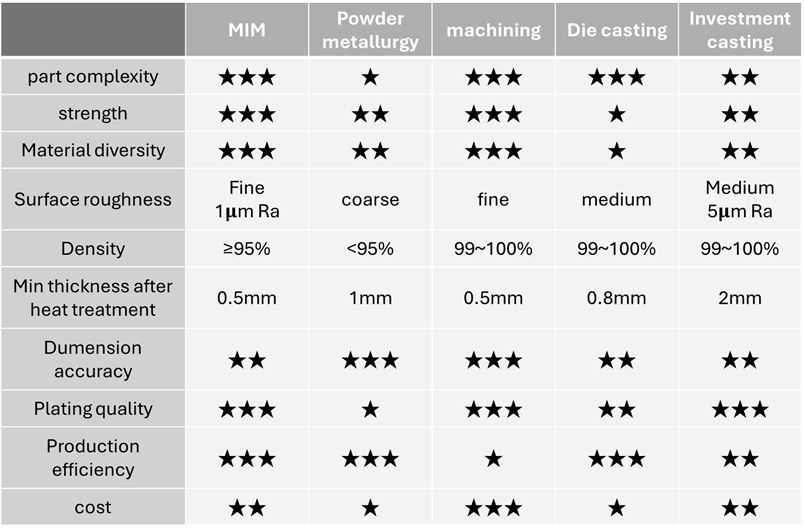

Traditional powder forming is mainly cold pressing and equal pressure forming. MIM uses finer metal powder than traditional powder metallurgy, and is formed in a similar plastic injection method. After sintering, the density and strength are higher than traditional powder metallurgy.

Advantage

1. High complexity and design freedom

MIM can create very complex and detailed shapes that are often difficult to achieve using traditional machining techniques.

2. High precision and surface finish

MIM enables very high dimensional accuracy, typically reaching a tolerance range of ±0.5%. And the final part usually has a good surface finish, reducing the need for subsequent processing.

3. Material diversity

MIM works with a variety of metals and alloys and can also handle specialty materials, such as high-melting-point metals and high-strength alloys, that are often difficult to form using other methods.

4. High material utilization rate

Compared to traditional machining methods, MIM offers higher material utilization while reducing material costs.

5. Mass production

MIM is ideal for high-volume production, using molds to ensure consistency and repeatability of each part, making it suitable for demanding industrial applications.

6. Superior mechanical properties

Sintered MIM parts typically have high density and mechanical properties, reaching 95% of the strength of ordinary materials.

7. Environmental protection

Compared with some traditional processing methods, the MIM process consumes less energy and reduces material waste due to high material utilization.

8. Improve efficiency

The MIM process can design multiple parts into a whole, reducing assembly steps, assembly costs and time.

Application

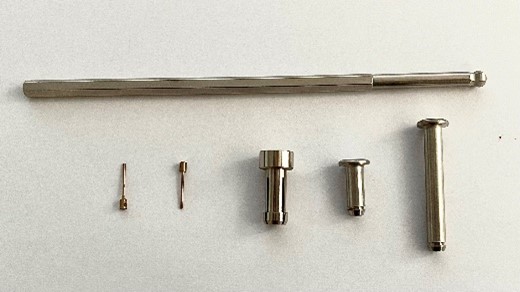

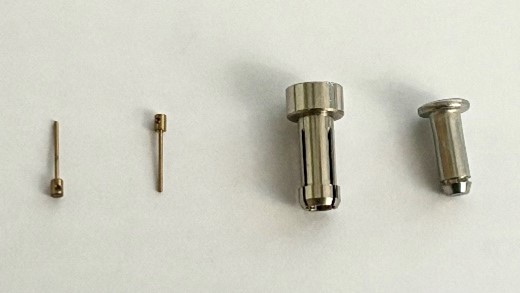

MIM process can be used in the medical industry, aviation industry, automobile industry, electronic products, etc. The following are some of the parts we could make for you for your reference:

In addition, please visit our webpage for more photos of our machined parts Machined Parts and Featured CNC Parts Gallery. We also provided the assembly service for clients, please visit Assembly.

Our machines and inspection equipment in our facility

Sintering Oven

Sintering Oven  Catalytic De-binding Machine

Catalytic De-binding Machine

Keyence OMM

Keyence OMM

Mitutoyo CMM

Mitutoyo CMM

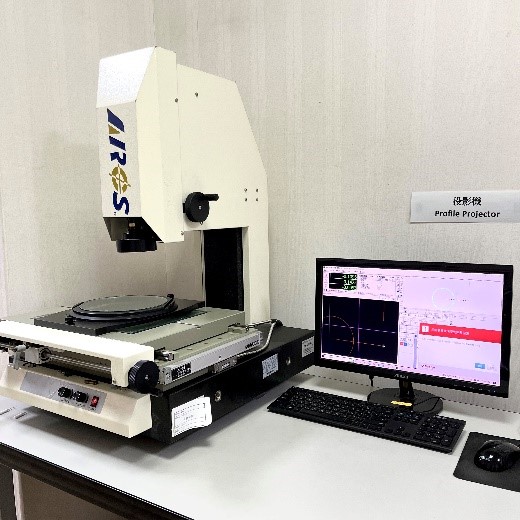

Profile Projector

Profile Projector

Micrometer Screw Gauge

Micrometer Screw Gauge

Swiss Trimos Height Gauage

Swiss Trimos Height Gauage Surface Roughness Measurement

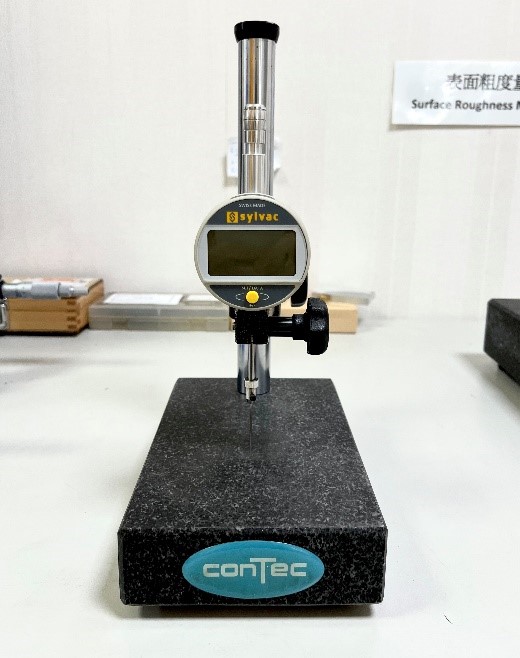

Surface Roughness Measurement

Digital Indicator

Digital Indicator

In addition, please visit the page Quality Inspection for more detail about our inspection equipment,

To ensure the precision of precision metal parts, Unison Tek leverages advance inspection facilities throughout our custom metal parts process. See the list below to find out more on our inspection equipments. Technical Data for your reference.

Unison Tek Co., Ltd. is ISO 9001:2015 Certified Machine Manufacturer in Taiwan for OEM/ODM/Customized machined products for 35 years. With professional engineering team, our team could help you reach your goal and make you more successful.

Unison Tek cointinued to grow a scalable company in Taiwan, and our goal is to serve all the clients who need oem machined metal parts (tooling part), and our team will reply to you with feedback in two working days.

Please get a quote from Harry Yen hyen@unisontek.com.tw All of us are looking forward to your good news and invite you to visit our factory in Taiwan. Welcome to send any inquiry to us! Please watch presentation of our company on YouTube Link.

2025 Copyright of UNISON TEK CO., LTD. © All Rights Reserved.